Benefits of Oatmeal

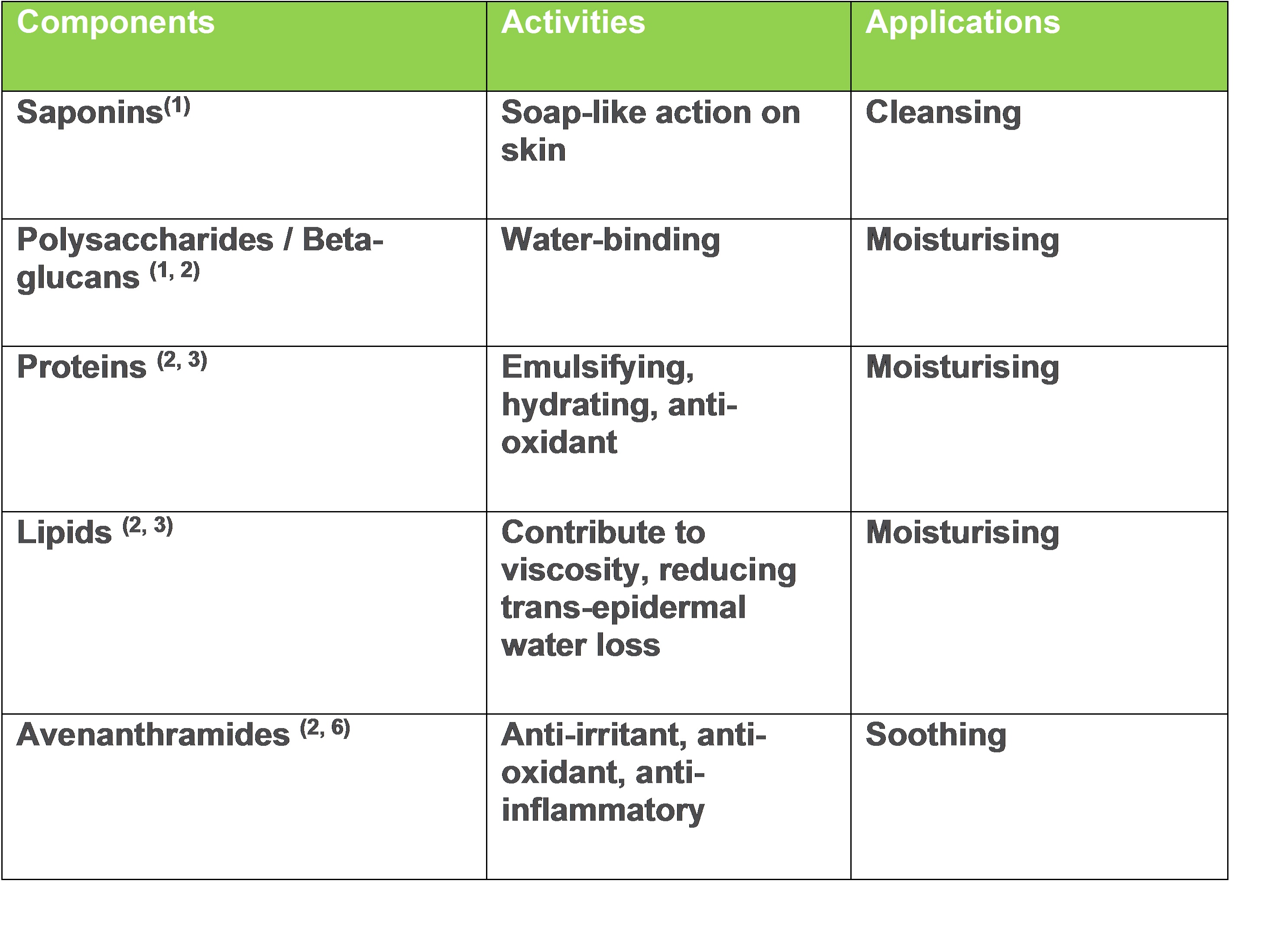

The composition of oatmeal gives many clinical properties including cleansing, buffering, moisturising, protecting, soothing, anti-irritant and antioxidant (1). Its beneficial components, which include proteins and lipids, are beneficial in the treatment of eczema and other inflammatory conditions (2).

Colloidal oatmeal preparations are an emollient of choice for a range of dermatology and other conditions, with dry skin as a symptom. A range of skin care emollient products, such as bath treatments, body washes and cleansing bars, creams and lotions, can be used to manage these conditions (2). In addition to its emollient properties, colloidal oatmeal also has protective, cleansing and moisturising functions which make it well suited for use in products which help to clean, soothe, and protect the skin (3).

History and Origin: Colloidal Oatmeal (oat flour)

Oatmeal baths have long been recommended for people with a variety of sensitive skin conditions, for the soothing effect they provide (4).

The use of oats for skin care dates back to Roman times. Indeed, numerous references can be found in Roman medieval literature to the use of oatmeal for medicinal purposes (1). The acclaim of oatmeal continued through to the nineteenth century where the use of oatmeal was advocated by dermatologists of the time. The process then involved soaking oatmeal in boiling water. It was recommended that the oatmeal was contained in a porous bag to avoid drain-clogging (4).

In 1945, a ready-to-use colloidal oatmeal, produced by finely grinding the oat and boiling it to extract the colloidal material, became available (1). AVEENO’s first colloidal oatmeal bath treatment was developed in conjunction with The Mayo Clinic the same year (5). Today, colloidal oatmeal is widely available in various forms including bath treatments, cleansing bars, body washes, shampoos, creams, lotions and shaving gels (1).

Cultivation and Harvesting

The makers of AVEENO® source colloidal oatmeal from oats (avena sativa) grown in regions that provide an ideal environment for the oat to grow, combining appropriate well drained soil and a cooler climate. Cooler temperatures and low humidity in these areas are also an advantage during storage, limiting the risk of preservation issues.

Processing

The manufacturing process for colloidal oatmeal is a process achieved without the use of chemical solvents. Oat grains with high protein content are selected for colloidal oatmeal production. Once harvested, the oats are stored in a mill elevator. The grains are cleaned to remove any foreign materials, imperfect grains, weed seeds and other grains. They are then de-hulled to remove the envelope or hull around the grains, yielding the groats. Steel cutters are used to reduce the groat size, starting the particle size reduction process. The groats are steam heat treated for stabilisation and to reduce free fatty acids to the lowest level. This also helps destroy bacteria and prepare the groat for rolling, flake integrity and water holding properties.

Oats contain a number of enzyme systems. Lipase is one of the most abundant enzymes in the oat. Lipase is the enzyme which causes hydrolysis or rancidity in the oat and must be inactivated to stabilise the oat. Its inactivation by steam heat reduces the release of free fatty acids, potentially irritating to the skin. Timing is critical as rancidity can be initiated within hours after the raw oat has been de-hulled. The oats are then rolled or flattened and then pulverized to the desired particle size resulting in colloidal oatmeal. This fine powder is then stored in a temperature and humidity-controlled area. The production of the colloidal oatmeal used in AVEENO® products comes from a dedicated production line assuring high quality standards.

Composition and Activity

Colloidal oatmeal is obtained from the whole oat grain (6).

- Oatmeal can help restore normal pH in skin conditions where pH has increased. In this setting, it acts as a buffering agent (3).

- The moisturising properties of colloidal oatmeal are provided by its high content of hydrophilic components. Moisturising is achieved through the combined action of proteins, carbohydrates and lipids (3).

- Starches are important constituents of colloidal oatmeal (7). They are highly hydrophilic and can absorb large quantities of water. Proteins contained in colloidal oatmeal further contribute to its water affinity (3). The unique lipid composition of colloidal oatmeal- which includes oat triglycerides and phospholipids, as well as oleic, linoleic and linolenic acids- participates in the formation of a film at the skin’s surface (3, 8).

- This occlusive, water-binding colloidal film holds moisture in the stratum corneum, improving dry skin conditions (1).

Table 1: Components, Activities, Applications / Contents of Oatmeal

References

1. Kurtz et al. Colloidal oatmeal: History, Chemistry and Clinical Properties, Journal of Drugs in Dermatology, 2007 6(2): pp167-170.

2. Van Onselen. Dry skin conditions: an evidence-based focus on natural oatmeal emollients, Primary Health Care, 2011 21(2): pp31-37.

3. Rinaldi et al. Colloidal Oatmeal, Characteristics, Properties, Clinical Applications. Scientific Library of Rydelle Laboratories, pp33-71.

4. Miller. Oat derivatives in bath products. Cosmet Toiletries, 1979 94: pp72-80.

5. Soothing Skin the Natural Way https://www.jnj.com/caring/patient-stories/soothing-skin-the-natural-way. Accessed 23rd November 2017.

6. Nebus et al. New Learnings on the Clinical Benefits of Colloidal Oatmeal in Atopic Dermatitis. Supplement to The Dermatologist, 2012.

7. Paton. Oat starch: physical, chemical and structural properties.Chemistry and Technology, 1986 American Association of Cereal Chemists, pp.93-120.

8. Zhou et al. Oat lipids. J. Am Oil Chem Soc, 1999 76: pp159-169.